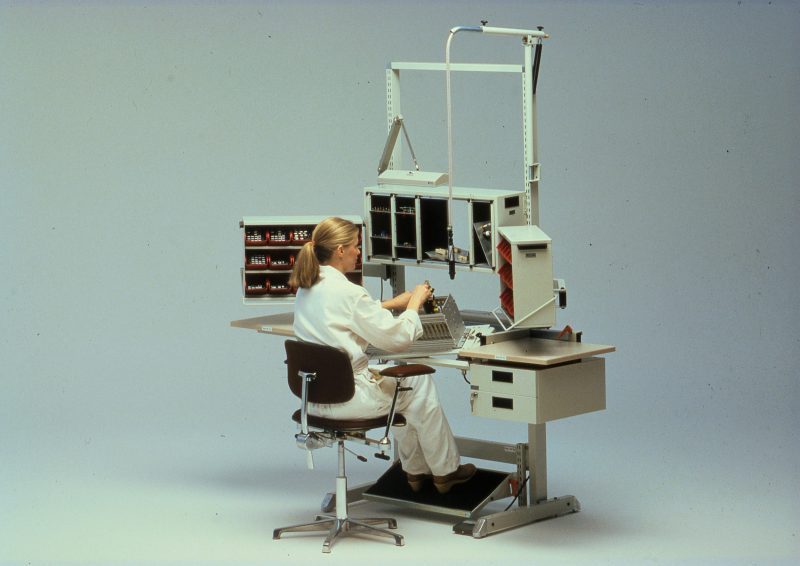

Assembly system for electrical industry

In 1980, G.W. Sohlberg Oy’s industrial furniture factory in Jyväskylä made the decision to develop a new furniture system with superior ergonomics suitable for short production runs in the electrical and electronics industry. The development task was carried out by a team consisting of the client’s product development team, a production economics consultant and a designer as an ergonomics expert.

The design paid particular attention to ergonomics, sizing, worker-specific adjustments and product-specific modification possibilities, as well as the production economy; flexible batch changeover, efficient factory lay-out and reduction of lead times, and generally raising the comfort and aesthetic level of the factory floor.

The project lasted about a year, during which the aim was to regularly measure the status of each stage of the development work using various ergonomics and work research indicators. The new concept of industrial equipment required the creation of a specific training package for production and marketing, as well as ergonomic and production-economy training for export companies, and the organization of training courses. With this new concept, GWS moved from Nordic exports to European markets, including England, France and Germany.