A design decision is a huge production decision

In the production of consumer commodities, annual production volumes are of tens of thousands. As a result, design solutions are huge production decisions. Design decisions are often made using life-size models. Although the models may seem laborious, they cost a fraction of the price of a single injection mould.

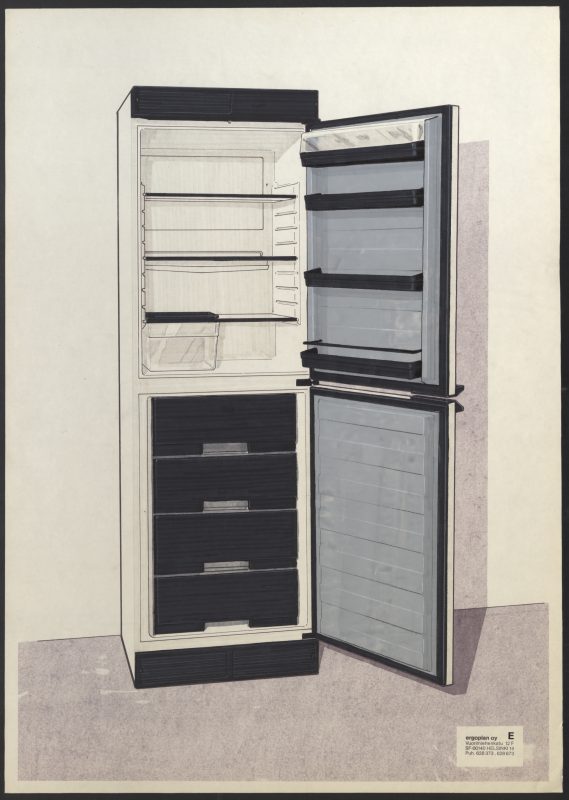

In 1985, Forste made the decision to switch to a circular door design for Helkama refrigerators and at the same time the entire door structure was redesigned. The door consists of a roll-formed steel outer shell, injection-moulded end sections, a vacuum-formed inner section and a rubber magnetic seal. The door is assembled in a semi-automatic foaming line, where insulating foam glues the entire door structure together.

The design decision was accompanied by a decision to purchase a new roll forming line and a door assembly line. Both lines had to be custom-made. Production started about a year after the design decision was made. The cost of the automatic roll forming line was around FIM 2-3 million. In 1990m they switched to more environmentally friendly CFC-free raw materials for insulating foam.