Design for salon-style convenience and competitiveness

In the 1970s, and still today, the most important goal in designing a consumer electronics product, or consumer electronics product, was its marketing features. This means that as many consumers as possible are prepared to choose the product and pay the price asked for it. Therefore, judging the appearance of a product on artistic grounds is pointless, the most important thing is its marketability. So, the more consumers like the look, the better it is. We strive to design what the people want. The difficulty is not knowing what the people want, or more dangerously, misunderstanding what the people want.

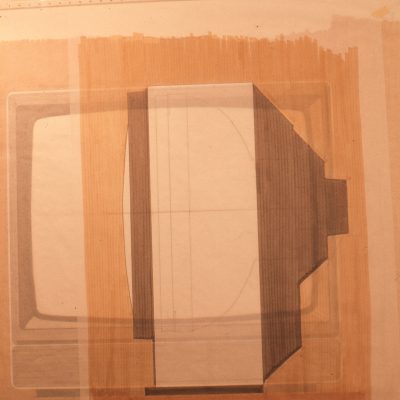

When potential buyers and sellers of the product were asked what features they wanted from the product under development compared to its competitors, the answers were regularly as follows: "It is good looking, it does more new tricks and it is cheaper". They really do not help. Thank God for fashion. Fashion serves manufacturers and is driven by technological harmonisation, but it can also be driven artificially. It's no coincidence that new cars look the same. In Finlux's case, this meant that while differentiation was needed to stand out from the competition, there could not be too much differentiation.

Due to competitive pressures, the need to lower the manufacturing price and technological advances, the producer must constantly and repeatedly bring new and unprecedented products to the market. Even then, the price of electronic products was falling, and new products were doing more tricks at a lower price. Especially in electronics, products are soon outdated.

If previously the consumer electronics industry in Finland had been seen as a substitute for imports, in the 1970s the focus was on exports. With the liberalization of imports, the price competitiveness of domestic manufacturers had collapsed and only an increase in production volumes improved competitiveness. Manufacturing prices could only be brought down by reducing human labour and investing in new capital-intensive technologies, such as the perceived modernity of plastics instead of wood and metal parts. This required an increase in production volumes to pay for the expensive tooling. Also, the more you bought, the cheaper you got the components from which the products were assembled. At Finlux, the plastic parts had been designed by Veikko Rintala and Pauli Saarinen, and new plastic skills were also desired from the future designer.